Biobased Maine Attends BDC Spring Forum in Florida

March saw Biobased Maine in Jacksonville, Florida for the Biorenewable Deployment Consortium’s (BDC) Spring Forum. BDC reported record attendance at their forum, including many important players from the forest products and biotechnology industries. Maine’s ND Paper, Sappi, and Verso all attended. Other notable national and international companies included Velocys, MetGen, Domtar Paper Company, Prisma Renewable Composites, and Irving. This year, the BDC Spring Forum touched on three important focus areas: 1) changing policy to remove barriers to the Forest Products Industry; 2) commercial progress of wood to bio-products; and 3) processes that add value, with a special focus on lignin.

Relevant to Maine within the first focus area was a presentation by Velocys. In his presentation, Velocys’ Commercial Director, Jeff McDaniel, highlighted the very restrictive definition of qualified feedstock under the Renewable Fuel Standard (RFS), and the resulting disadvantages to Maine because our naturally regenerating and sustainably harvested wood does not qualify. McDaniel pointed out Velocys’ interest in Maine’s available wood and existing industrial infrastructure, but says that until the RFS definition of qualifying feedstock is revised to include Maine wood, it is not economically feasible for Velocys to locate in the state.

Several companies reported exciting commercial progress of wood to bioproducts, including Canfor Pulp’s commercial project with Licella in Prince George, British Columbia. Their joint venture to develop and license the integration of the Cat-HTRTM platform into mechanical and Kraft pulp mills is moving full steam ahead. The initial commercial plant will be one of the largest 2nd generation biorefinery in the world, producing biocrude at 500,000 bbl/year. Velocys reported their Red Rock Biofuels facility in Lakeview, Oregon is in the deployment phase, meaning they have begun to receive and integrate reactors into the facility. Meanwhile, the wood to fuels project in Natchez, Mississippi has successfully produced sustainable fuels and generated D7 RINs. However, even in Natchez, Velocys reported that some attractive feedstocks do not qualify for RIN credits under the RFS. Further, Attis Innovations presented their commercial plans for Barnesville, Georgia, where they will convert 200 tons per day of dry southern yellow pine wood chips into 12,000 tons per year of ethanol and 27,000 tons per year of lignin polymers. Attis Innovations is also planning a commercial project in Fulton, New York to use their newly purchased ethanol plant as a campus for developing new bioprocesses.

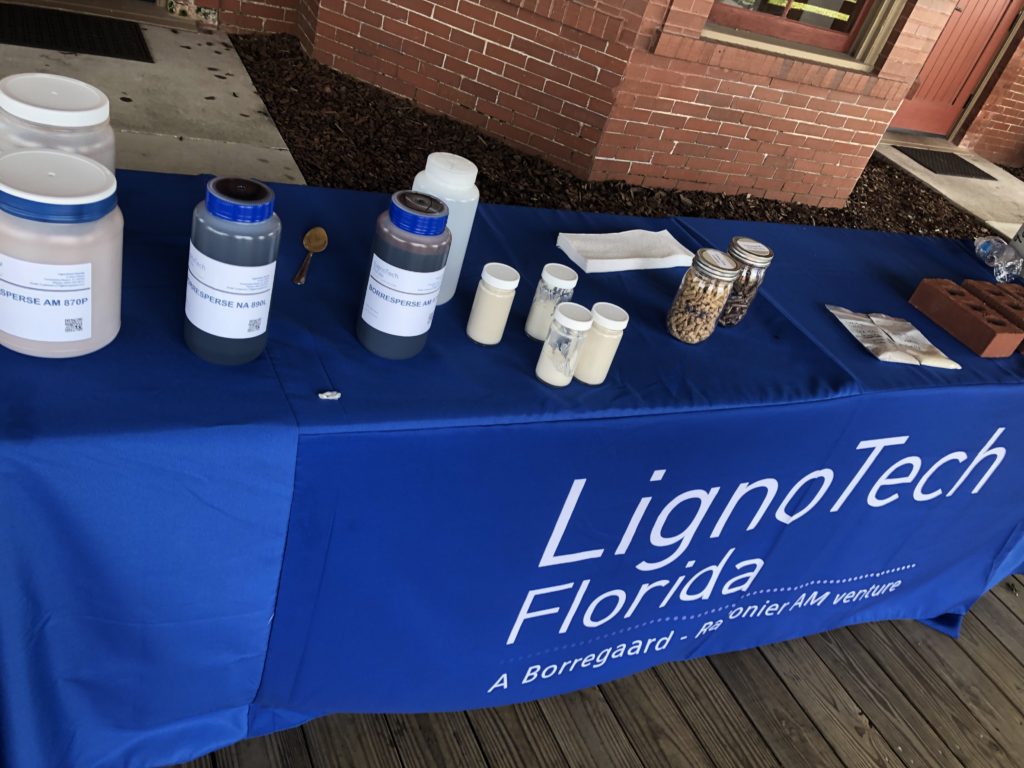

While at the BDC forum, Biobased Maine learned a great deal about lignin, and the variety of high-value applications thereof. While lignin can be burned and used for power generation, there are better applications of lignin that add value, and are better for the environment. For example, lignin can act as a “rebar” when mixed into cement, and can also be used in the production of bioplastics, adhesives, carbon fiber, and even in batteries. Jerry Gargulak, Business Development Manager at Borregaard/LignoTech says soil conditioners for crop production may be the fastest growing use for lignin.

The forum culminated with a bus tour of the Rayonier Advanced Materials pulping operations, and the LignoTech Florida facility on Fernandina Beach. LignoTech Florida is owned by Borregaard and Rayonier Advanced Materials, and produces high performance dry lignin products for sale in the construction and other markets. In fact, Borregaard claims their dry lignin could reduce the need for water in cement, can be used to make stronger decorative bricks, and can help bind lime powder, so that when it’s run through a simple spreader, it will drop small pellets exactly where the customer wants them to go rather than blowing around in the wind as powder.

BDC is a non-profit organization which focuses on education and brokering partnerships to accelerate the commercial deployment of biotechnologies and assist the forest products industry in positioning itself as a leader in the field of biorenewable products.